Hydroforming Sheet Metal And Device

For more than 40 years hydroform usa has led the way in all sheet metal applications by employing lean practices to manage large build packages including stretch forming brake and roll forming hydro forming cnc machining and chem paint.

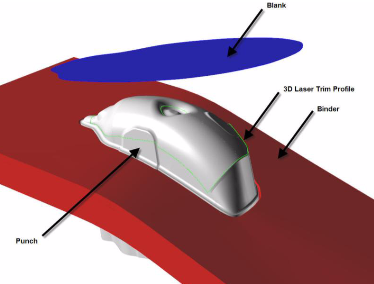

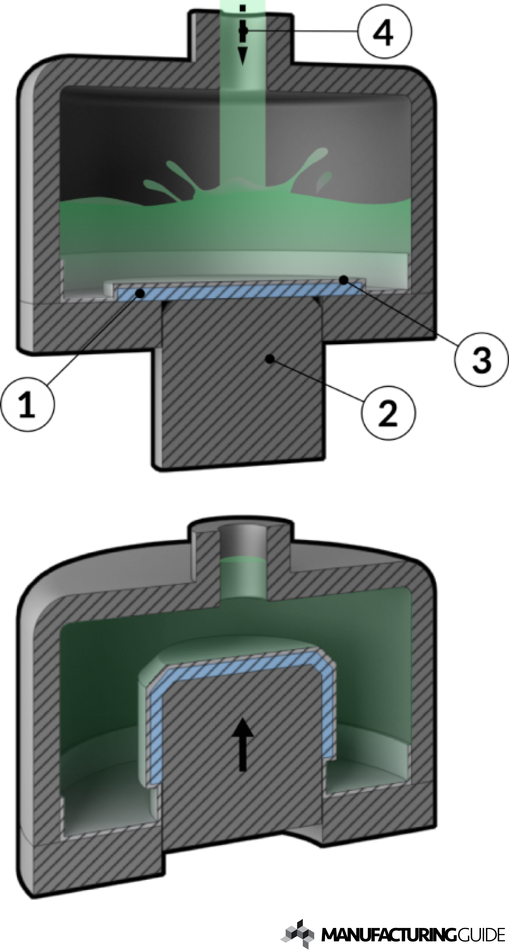

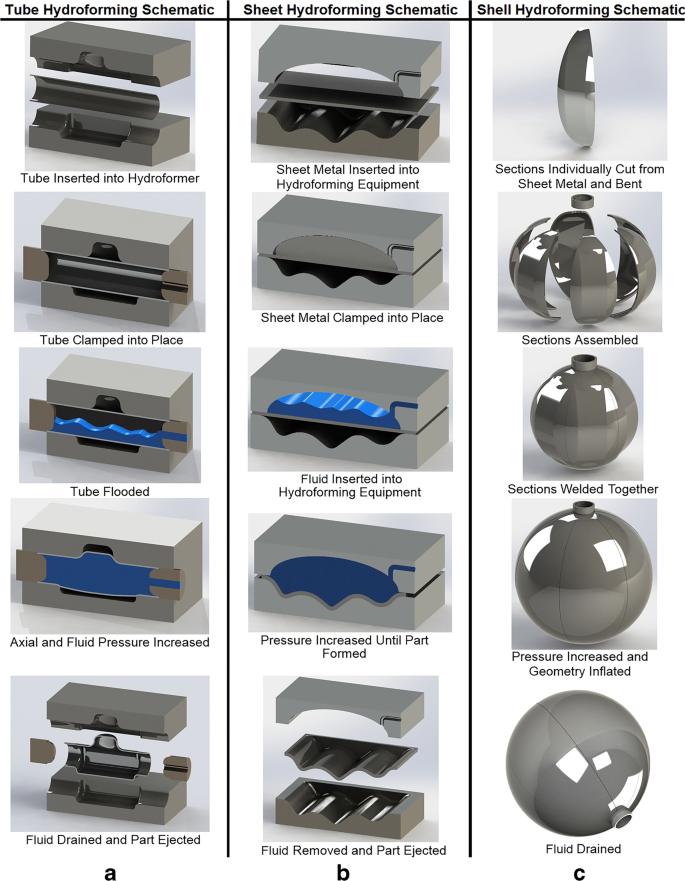

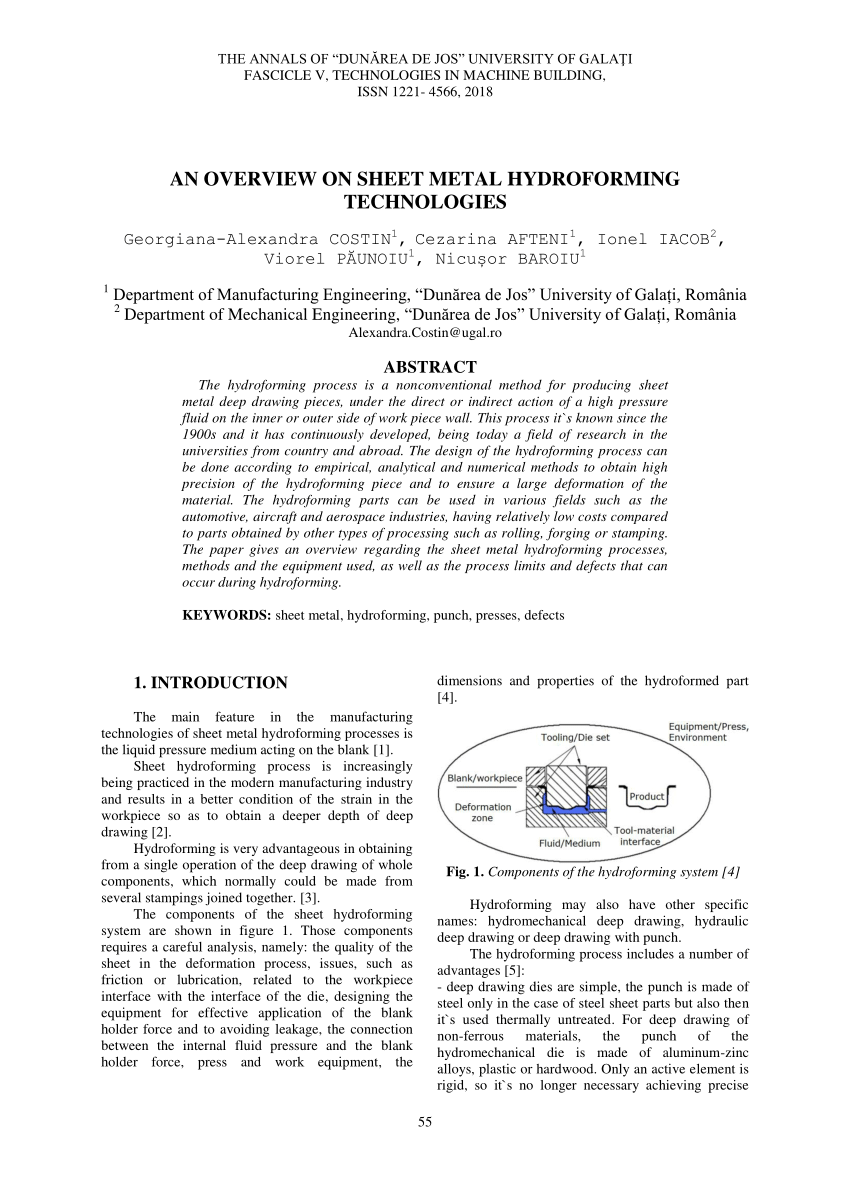

Hydroforming sheet metal and device. The basic die includes an upper shoe 15 mountable to the outer slide 11 and hydraulic cylinder assemblies 17 18 mounted on the base and actuable by the inner slide for providing pressurised fluid to the tooling. Numerous industries for example the manufacturers of automotive components and the piping industries which are providing mass products apply this technology productively. The device has base and outer 11 and inner 12 slides and including a basic die 15 16 17 18 mountable to the press and tooling 25 51 mountable to the basic die. Virtually all metals capable of cold forming can be hydroformed.

With up to 4x the pressure used by traditional hydroforming devices highly complex medical equipment components and devices with can be formed with ease. Manufacturing and assembly for the aerospace industry. It is the preferred technique for shaping intricate components from ductile metals. Hydroforming is a metal forming technology based on the application of pressurized liquid media to generate defined workpiece shapes from tubular materials or sheet metals.